The valves for the conventional pressure РN320 [32,0 MPa (320 kgf/cm2)]

The valves for the conventional pressure РN250 [25,0 MPa (250 kgf/cm2)]

The valves for the conventional pressure РN160 [16,0 MPa (160 kgf/cm2)]

|

Application The control single-seat valves are stationary elements of automated control systems for technological processes and they are meant for controlling the flow discharge of the working medium in automated control systems for technological processes. The valves of type ПОУ 29Р and ПОУ 30Р are applied in the production of methyl and butyl alcohol, ammonia, oil products. The valves of type ПОУ 29Р/1Т and ПОУ 29Р/2Т are applied in control systems of the production process of the high pressure vapor. The valves of type ПОУ 29Р/3Т are applied for the control of vapor supply to reheaters in departments for direct hydration of synthetic alcohol productions. The valves of type ПОУ 29Р/4Т are applied for the control of vapor supply for mixing with ethylene in departments for direct hydration of synthetic alcohol productions.

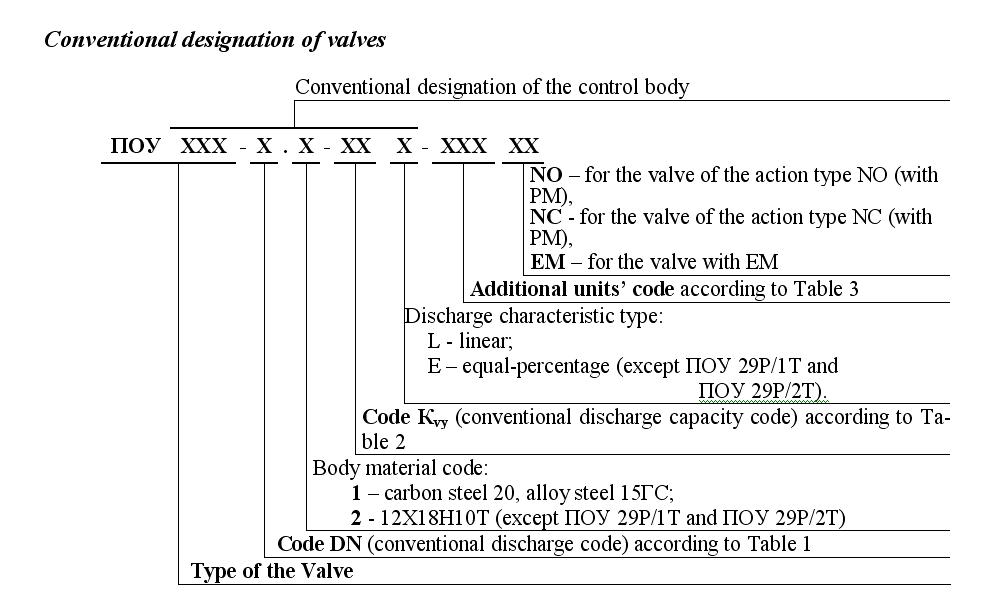

Characteristics The control single-seat valves with angular body, with gland rod seal, with the pneumatic (PM) or electrical (EM) executive mechanism (drive). Action type of the valves with the pneumatic drive: normally open (NO) or normally closed (NC). The type of the discharge characteristic: linear (L) or equal-percentage (E). The type of the climatic performance of the valves: У1 according to GOST 15150-69, but for operation under temperature from minus 50 °C up to plus 50 °С. The sound level, created by the valves, doesn’t exceed 80 dB·A. |

|

The material of the basic parts, which directly touch the medium controlled, correspond to the material of the body, excluding the plunger and the closure seat.

The plunger and the closure seat of the valve ПОУ29Р are made of stainless steel 14Х17Н2 and 12Х18Н10Т correspondingly with the built-up welding of the working part with electrode ЦН-2 or ВЗК (stellite) (for pressure differential up to 16 MPa) or with press-fitting of the working part of the alloy ВК-6М (for pressure differential from 16 up to 32 MPa).

The plunger and the closure seat of the valve ПОУ 30Р are made of steel 12Х18Н10Т with the built-up welding with electrode mark ЭЛЗ-НВ-1.

The body parts of the valves ПОУ 29Р/1Т and ПОУ 29Р/2Т are made only of carbon steel 20 or alloy steel 15ГС, the plunger and the closure seat are made of steel 95Х18. The interchangeable plunger is made of steel 20ХН.

Table 1

|

Code DN |

1 |

2 |

3 |

4 |

5 |

6 |

7 |

8 |

9 |

|

Port area |

DN10 |

DN15 |

DN25 |

DN32 |

DN40 |

DN65 |

DN80 |

DN100 |

DN20 |

Table 2

|

Code Кvу |

01 |

02 |

03 |

04 |

05 |

06 |

07 |

08 |

09 |

|

Conventional discharge capacity Кvу, m3/h |

0,10 |

0,16 |

0,25 |

0,40 |

0,63 |

1,00 |

1,60 |

2,50 |

4,00 |

|

Code Кvу |

10 |

11 |

12 |

13 |

14 |

15 |

16 |

17 |

– |

|

Conventional discharge capacity Кvу, m3/h |

6,30 |

10,00 |

16,00 |

25,00 |

40,00 |

63,00 |

100,00 |

5,00 |

– |

Table 3

|

Additional units’ code |

Additional units |

|

Pneumatic executive mechanism |

|

|

02 |

Pneumatic positioner |

|

02Э |

Electric pneumatic positioner. |

|

05 |

Pneumatic positioner and MA |

|

05Э |

Electric pneumatic positioner and MA |

|

Electrical executive mechanism |

|

|

11В |

Explosion-protected EM with MA (without a positioner) |

|

15В |

Explosion-protected EM with a positioner and MA |

|

11 |

EM of the general industrial performance with MA (without a positioner) |

|

15 |

EM of the general industrial performance with a positioner and MA |

Recommended types of the applied additional units are given in Table 4.

Table 4

|

Additional units or devices |

Recommended types |

|

Manual alternate |

Side manual alternate (SMA) |

|

Pneumatic positioner |

OJSC “Saranskiy priborostroiteliy zavod”, the firms “Samson”, “Siemens”, “smC” |

|

Electric pneumatic positioner |

OJSC “Saranskiy priborostroiteliy zavod”, the firms “Samson”, “Siemens”, “smC” |

|

Explosion-protected EM with MA (without a positioner) |

“ZEiM” Cheboksary, “ChEAZ” Cheboksary, “Tulaelectroprivod” |

|

Explosion-protected EM with a positioner and MA |

The firms “AUMA”, “ROTORK” |

Operating position of the valve – any, preferably vertical (executive mechanism up).